How we designed Field lids

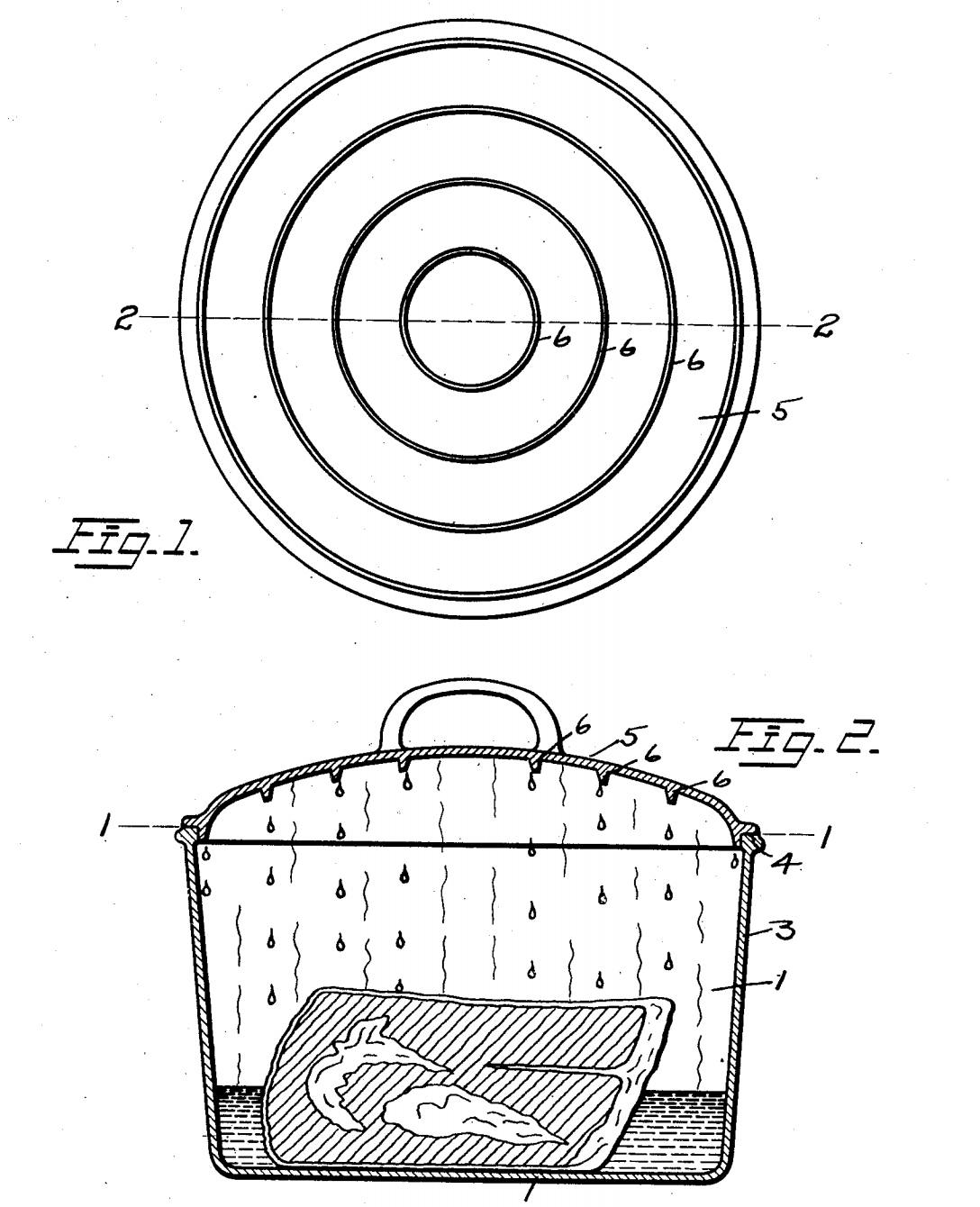

In the early days, the Field Skillet stood alone — a versatile kitchen tool that's ready for anything — but research into the vintage classics and observation in the kitchen led to an obvious conclusion: you end up reaching for a cover more often than you think, and a well-sized, self-basting lid really expands the possibilities for cooking with a cast iron skillet.

Field Skillets draw inspiration from the lighter, smoother skillets of America’s cast iron manufacturing heyday — especially vintage pieces by Griswold, of Erie, PA, and Wagner, of Sidney, OH. For our first lid, we stuck to the design principles of the Field Skillet — it's lightweight, too, and matches the simple silhouette of our original pan — and put our spin on a century-old cast iron innovation.